|

|

Post by boxer64 on Apr 28, 2014 10:12:47 GMT -8

Great work Robert,

Eddy

|

|

|

|

Post by rnagle on May 9, 2014 17:15:13 GMT -8

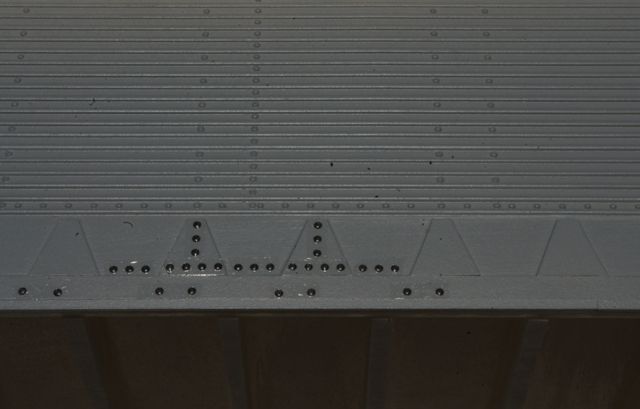

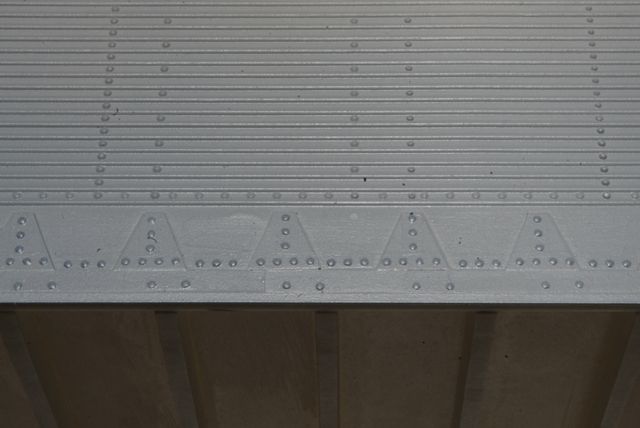

Back to "active" status for the Carling O'Keefe van, as kit represents a Fruehauf and one I am modelling is a Trailmobile some visual sleight of hand required along bottom edge of trailer. Area below corrugations sanded smooth and lip along bottom edge built up with styrene strip. Gussets cut from .010 x .250 strip and attached using rivet lines on corrugated sides as a guide.  Rivet decals from Micro-Mark used, their O scale (1:48) set works well on 1/25 trucks. After application and a couple rounds of decal solvent the clear film effectively disappears under a coat of primer.   |

|

|

|

Post by ap40rocktruck on May 14, 2014 4:41:51 GMT -8

DANG, such commitment to detail!

Ap40

|

|

|

|

Post by rnagle on May 17, 2014 17:32:16 GMT -8

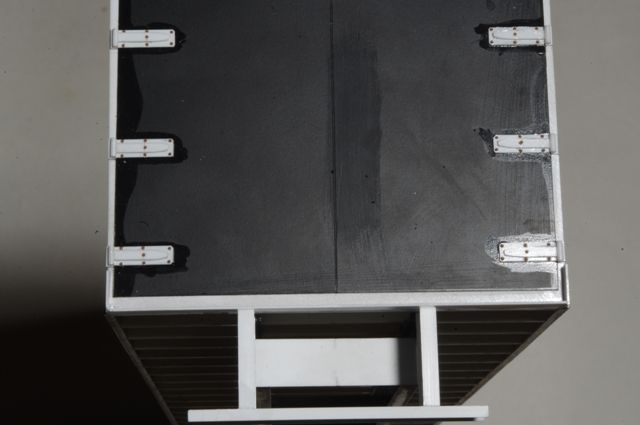

Thanks Rick - I do admit somtimes I think it would be easier just to build the stock kit and paint it Carling colours (Fruehauf, Trailmobile, what's the difference?  ), in the end this is far more rewarding though. Continuing with use of "leftovers", Italeri suspension and slider rails were on hand from a previous beer trailer project (Labatt's 4 axle van), basic suspension "box" assembled and given styrene overlays as this was easier than filling/puttying/sanding the holes. Springs and mounts will be sourced elsewhere as the Italeri springs don't match 1:1 trailer's suspension.  Doors are .010 styrene overlay with hinges built up from styrene strip & rod. Rivets here are Tichy Train Group parts, it was actually easier to drill and install these than apply single decal rivets - I know because that was the first approach I tried.  ICC bar is 5/16" styrene I-beam uprights with 5/16" channel crosser.  |

|

|

|

Post by gatorincebu on May 18, 2014 7:55:01 GMT -8

Robert,

Model building is for most a hobby to enjoy and relax with, If you enjoy the finite detail and correcting of things to match your subject. Well then That is a plus. like you say" it is more satisfying!" Though there might come the time when a well done box stock will help to get the creative juices flowing again.

I commend your talent and skills and attention to detail.

Be Well

Gator

|

|

|

|

Post by Robert Myers on May 18, 2014 9:01:18 GMT -8

That is amazing detail!!!!!

|

|

|

|

Post by rnagle on May 22, 2014 15:44:35 GMT -8

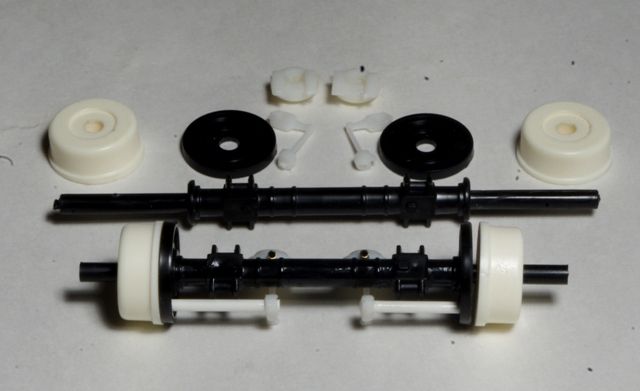

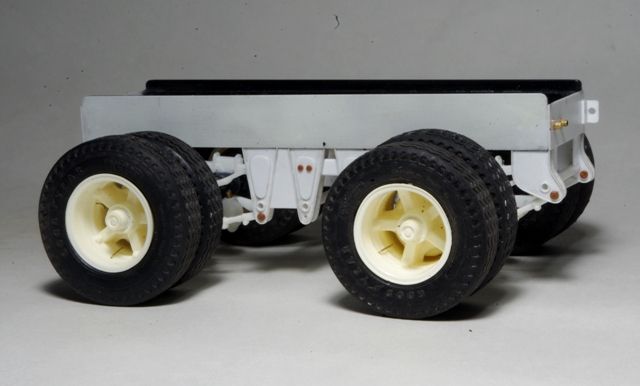

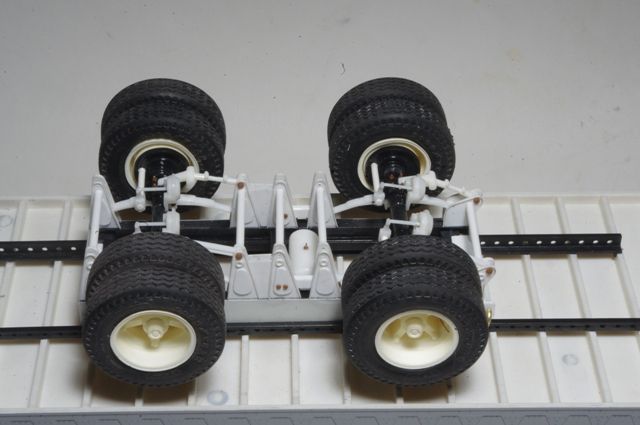

Thank you Robert and Gator, axles are again a mix & match of leftover parts - with some new material as well (resin brake drums from Plaskit, the entire meal doesn't have to be "leftovers" does it?  ) Axles on the real trailer are round so the Italeri ones from "American Cargo Trailer" kit are a good match along with brake backing plates. AMT 40' van kit brake chambers and slack adjusters used, 1/16" thin wall brass tube for fitting where hose will attach to brake chamber and .080 styrene rod connecting slack adjuster to backing plate.  |

|

|

|

Post by rnagle on May 31, 2014 2:17:17 GMT -8

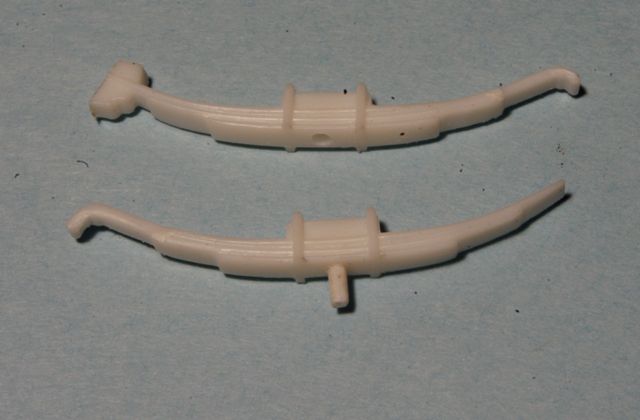

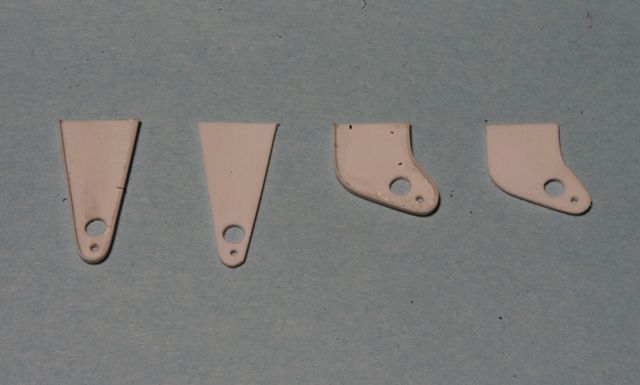

A couple of trailers made from AMT parts a while back used suspension brackets from 2 kits to get wider axle spacing, this left some springs in the spares box. Cleaned up and drilled for 1/16" styrene mounting pin, these will work nicely under this trailer.  Brackets did require "new material only", .020 styrene body with .010 x .040 flange. |

|

|

|

Post by jimb on May 31, 2014 17:21:29 GMT -8

Nice looking brackets.

|

|

|

|

Post by rnagle on Jun 5, 2014 14:09:57 GMT -8

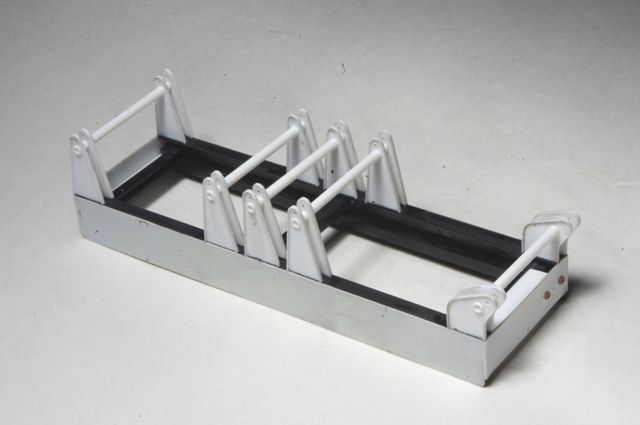

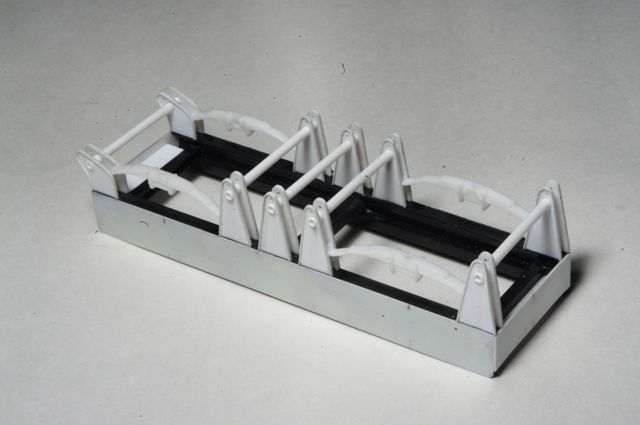

Thanks Jim - only "problem" is, there are so many of them! And this is only a tandem! Brackets in place on suspension frame:  And springs in place. Still a bunch more items to add such as additional gussets and the equalizer bar between front and rear spring sets.  |

|

|

|

Post by rnagle on Jun 6, 2014 16:18:55 GMT -8

Kingpin made from pieces of 3/32 brass tube soldered to 1/16" brass rod. Easy to make and much stronger than kit supplied plastic part - no clean up of parting lines either.   |

|

|

|

Post by rnagle on Jun 13, 2014 15:34:50 GMT -8

Suspension assembly complete, track rods are again "leftover" items from spare (AMT trailer) kit parts collection. Triangular raised areas on suspension brackets made from .020 styrene sheet, wheels and brake drums are resin items from Plaskit. Fastener details added using Tichy Train Group parts.   |

|

|

|

Post by rnagle on Jun 30, 2014 9:20:06 GMT -8

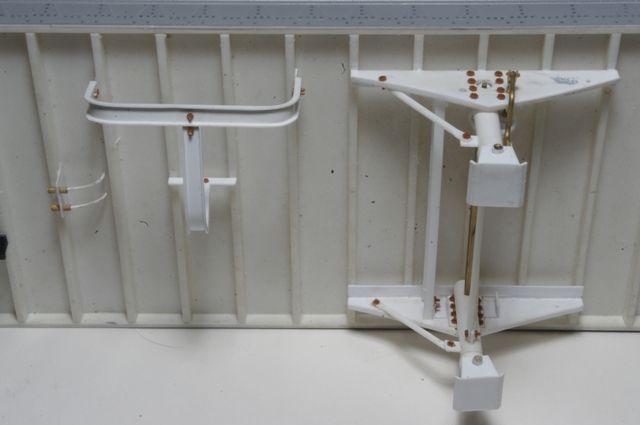

Landing gear required scratchbuilding as there were no "leftover" kit parts close enough to match 1:1 version, still to be added are the gearbox and crank handle:  |

|

|

|

Post by rnagle on Jul 14, 2014 16:18:56 GMT -8

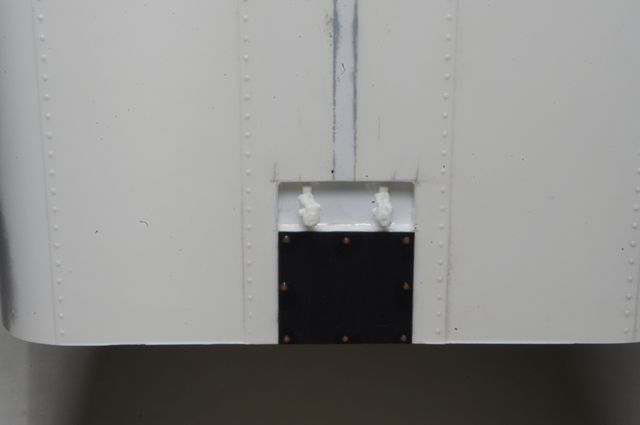

Rest of landing gear details completed, crank handle formed from 3/64" brass wire. Spare tire holder is 3/16" styrene channel clamped to a form then heated in boiling water.  3/64" brass wire also used for door lock rods along with styrene and brass strip and rivet head detail castings from Tichy Train Group.  And up front, of course I had to pick a 1:1 trailer that had recessed area where glad hands attach.......in this situation overscale thickness of kit plastic parts works to advantage. Glad hands themselves are resin parts from Plaskit.  |

|

|

|

Post by gatorincebu on Jul 19, 2014 8:40:55 GMT -8

Robert,

Your attention to detail is amazing. I hope to be able to utilize what I am learning from you. When I get back to the Philippines.

Be Well

Gator

|

|