Post by Muleskinner on Jun 13, 2012 21:54:42 GMT -8

Out here when a logging company gets a call for a job hauling peeler cores from a Plywood mill, they have what they call a Hay Rack spanner which converts a long logger logging truck into a conversion for hauling cores.

Peeler cores are the left over centers of the log after the head rig planner has shaved the veneer sheets off of them. They are usually 6 - 8 inches in diameter and 8 - 9 Foot long. These cores are sold or sent to other manufacturers to be made into fence post or decorative sign posts in cities or our National Parks. Since they are to short to haul on a normal logging truck, this is where the Spanner Hay Rack comes in.

The unit is built to be mounted on the normal bunks of a long logger and then chained down tightly to the bunks. They are rigid frame units which have two stationary bunks mounted in the center at the length which will handle the cores. Once the unit is mounted to the truck, a normally flexible logging truck becomes a rigid trailer unit. This unit came about as it is easier to convert to this system than it is to purchase a normal hay rack and convert to a fifth wheel unit. Even though with the decline of the Timber industry here in the Pacific Northwest has led to the closure of a lot of Plywood Mills, a lot of trucking units still have the Hay Rack Spanners laying around.

Some were shop built to cut expenses and others were built by some of the trailer builders here in the Northwest. Below is a typical unit built by Wit-Log over in Roseburg, not to far from here where I live in Oregon.

This unit is owned by Schaffer Logging which is across the road from me here in Norway, Oregon. It is seldom used and has been laying beside the road for many years even though it is in Practically new condition. This is the way a lot of them have ended up with all the closures of Mills.

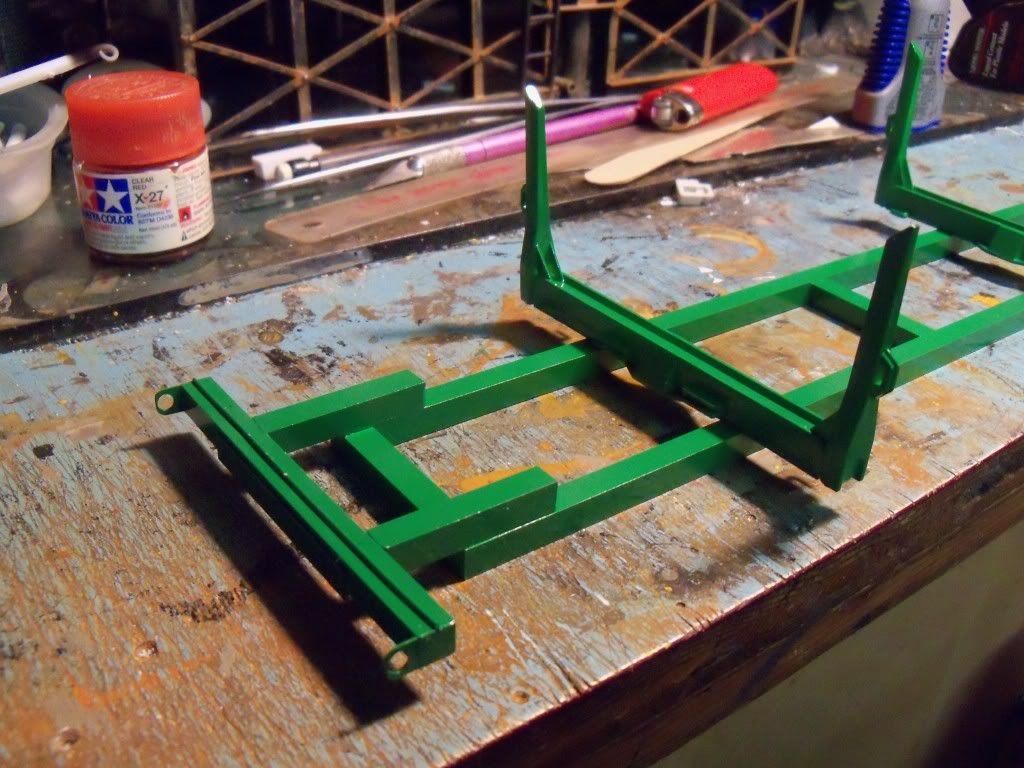

I was looking at it today and decided I would build my own version of it in 1/25Th scale as if a logging outfit needed one right away and had no time to buy one. Since there is always a pile of steel Bar and various other items laying around the shops, I decided to build as if the shop built it. I used .250 x .250 (1/4 x 1/4') evergreen dimensional strips # 199 for the basic frame and end cross members which lock into the bunks and a old set of AMT logging bunks for the center racking units. This was about a two hour project. The whole unit scales out to 28 scale feet in 1/25Th scale. Below are the results of this build Laying free and mounted on one of my older (Prehistoric) builds with cast ERTL Bunks on it. See Below.

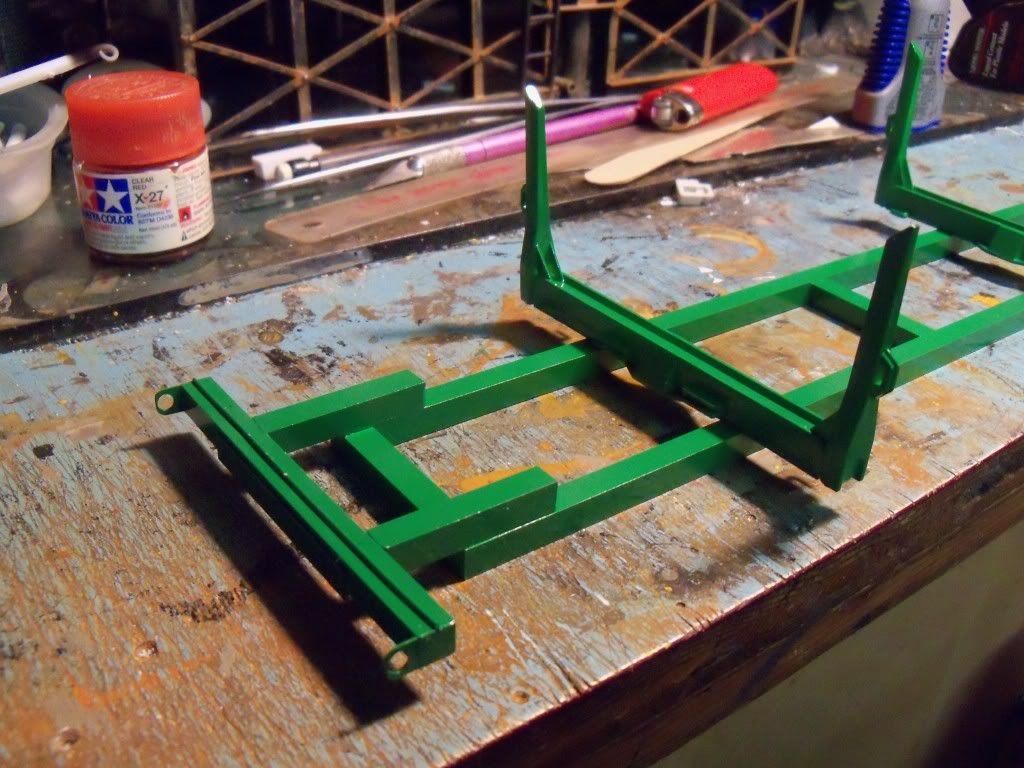

As you can see the project fits quite nicely on the Logging truck and give a better idea of the setup. It will not remain on this rig but will be put on another which I have in the planning stages for future build.

A final note here concerning this setup. Some units still use them who hire out to the Forest Service and BLM for cleanup of old snags and slag units in the forest floors to prevent fires. This wood is mostly what ends up chipped and used for animal bedding on farms and ranches or Landscaping material for gardens.

Peeler cores are the left over centers of the log after the head rig planner has shaved the veneer sheets off of them. They are usually 6 - 8 inches in diameter and 8 - 9 Foot long. These cores are sold or sent to other manufacturers to be made into fence post or decorative sign posts in cities or our National Parks. Since they are to short to haul on a normal logging truck, this is where the Spanner Hay Rack comes in.

The unit is built to be mounted on the normal bunks of a long logger and then chained down tightly to the bunks. They are rigid frame units which have two stationary bunks mounted in the center at the length which will handle the cores. Once the unit is mounted to the truck, a normally flexible logging truck becomes a rigid trailer unit. This unit came about as it is easier to convert to this system than it is to purchase a normal hay rack and convert to a fifth wheel unit. Even though with the decline of the Timber industry here in the Pacific Northwest has led to the closure of a lot of Plywood Mills, a lot of trucking units still have the Hay Rack Spanners laying around.

Some were shop built to cut expenses and others were built by some of the trailer builders here in the Northwest. Below is a typical unit built by Wit-Log over in Roseburg, not to far from here where I live in Oregon.

This unit is owned by Schaffer Logging which is across the road from me here in Norway, Oregon. It is seldom used and has been laying beside the road for many years even though it is in Practically new condition. This is the way a lot of them have ended up with all the closures of Mills.

I was looking at it today and decided I would build my own version of it in 1/25Th scale as if a logging outfit needed one right away and had no time to buy one. Since there is always a pile of steel Bar and various other items laying around the shops, I decided to build as if the shop built it. I used .250 x .250 (1/4 x 1/4') evergreen dimensional strips # 199 for the basic frame and end cross members which lock into the bunks and a old set of AMT logging bunks for the center racking units. This was about a two hour project. The whole unit scales out to 28 scale feet in 1/25Th scale. Below are the results of this build Laying free and mounted on one of my older (Prehistoric) builds with cast ERTL Bunks on it. See Below.

As you can see the project fits quite nicely on the Logging truck and give a better idea of the setup. It will not remain on this rig but will be put on another which I have in the planning stages for future build.

A final note here concerning this setup. Some units still use them who hire out to the Forest Service and BLM for cleanup of old snags and slag units in the forest floors to prevent fires. This wood is mostly what ends up chipped and used for animal bedding on farms and ranches or Landscaping material for gardens.

), the trees here aren't as tall as ones out west.

), the trees here aren't as tall as ones out west.