|

|

Post by rnagle on Dec 11, 2013 17:29:49 GMT -8

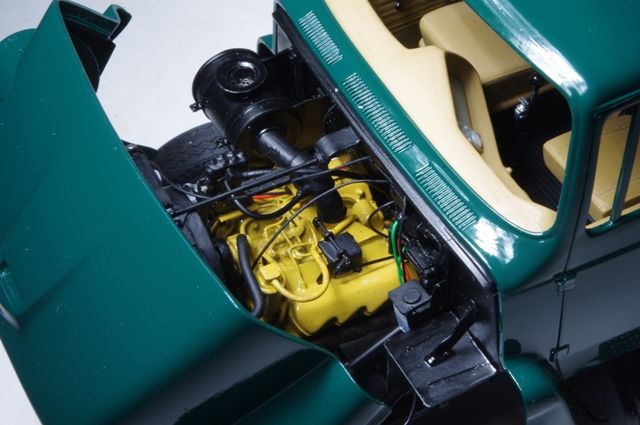

With green paint on it looks a little more like the "Big K" now. Still haven't weathered under hood yet but it will get done, too clean for a hard working fleet tractor right now....... Representation of throttle linkage and washer bottle made up from styrene & brass wire.   |

|

|

|

Post by gatorincebu on Dec 12, 2013 4:49:36 GMT -8

Robert,

You are right! That is way too clean to be a fleet tractor, even if it was steam cleaned or pressure washed!! lol Looks good though. and I like the green.

Be Well

Gator

|

|

|

|

Post by jimb on Dec 12, 2013 5:49:09 GMT -8

This is looking great!

|

|

|

|

Post by ap40rocktruck on Dec 12, 2013 7:36:52 GMT -8

Just keeps getting better & better. I agree with Gator, love that green! What color is it?

Ap40

|

|

|

|

Post by darkness21 on Dec 12, 2013 14:33:10 GMT -8

Looking awesome the green is cool the work you put into this is just beautiful.

|

|

|

|

Post by rnagle on Dec 12, 2013 15:10:16 GMT -8

Thanks everyone, green is hardware store spray paint, decanted & airbrushed. It is from the Canadian chain Home Hardware, their "house brand" is Beauti-Tone. I used the alkyd enamel forest green. Seems to match my 1:1 photo fairly well, admittedly colour match is highly subjective. I'll just make sure that particular photo gets displayed with model at shows!

|

|

|

|

Post by plastictrucker on Dec 13, 2013 8:39:14 GMT -8

that colour is perfect.I like it show room new looking.

|

|

|

|

Post by rnagle on Dec 19, 2013 17:57:02 GMT -8

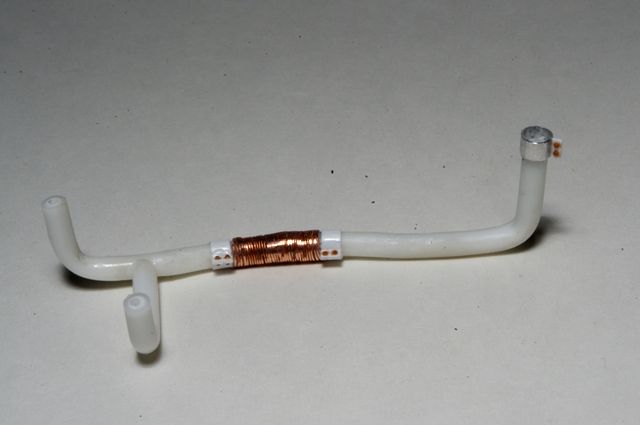

Thanks Kevin, a bit of progress since last weekend:  The "office" is just about done, only have fan to build & place on dash. Dash itself is mostly kit parts with turn signal switch and trailer spike added. Free standing brake knobs made from styrene strip & .030 rod.  Headliner made from Evergreen scribed sheet, sunvisors cut from .030 styrene sheet. Radio console is kit part with radio faceplate detail built up from styrene strip & disks.  Exhaust pipe is styrene tube with 1/8" rod inside, heated & bent as required. Holes slip over brass wire pins that were installed in exhaust manifolds prior to their assembly to engine. Flex pipe section is copper wire wrapped tightly around then filed to flatten contour out slightly. Band clamps made from styrene strip at either end of flex pipe section, aluminum tube at far end where pipe to stack will join exhaust system at final assembly. |

|

|

|

Post by ap40rocktruck on Dec 19, 2013 18:07:55 GMT -8

Frakin awesome level of detail. Nice to have a few other tricks to add to memory!

Ap40

|

|

|

|

Post by gatorincebu on Dec 20, 2013 2:30:29 GMT -8

OMG!!!!!!!!!!!!!!!! just when I think there isn't anything else to detail!!!!!!!!!!

Be Well

Gator

|

|

|

|

Post by rnagle on Jan 4, 2014 12:38:17 GMT -8

Some "modelling inactivity" the past couple weeks hasn't been all bad as green has had plenty of time to cure so today was mask & paint black. Some more curing time is in order then decals will go on.  |

|

|

|

Post by gatorincebu on Jan 5, 2014 19:17:23 GMT -8

QQ OMG it is getting close to being finished! Looking good!

Be Well

Gator

|

|

|

|

Post by kerry on Jan 7, 2014 4:05:58 GMT -8

Wow, that is looking great...

|

|

|

|

Post by trailking120 on Jan 9, 2014 8:40:06 GMT -8

The detail is just out of this world.  |

|

|

|

Post by rnagle on Jan 9, 2014 17:58:25 GMT -8

Thanks guys! One area kit parts can be improved on is mirrors, kit ones are the right basic shape however rather coarse. .030 styrene rod used for replacements, it can be flattened on the ends just like real mirror bracket parts. .015 x .040 strip used for flat portion against door, kit mirror heads are used with a small amount of reshaping. Bolt and rivet head details from Tichy Train Group, brackets tack glued to old parts box cab for assembly. Entire mirror will eventually be removed for paint & Alclad.  |

|